Advanced Cone Crusher Sleeve Bearing

Description

Basic Info.

| Model NO. | Customized |

| Material | Bronze |

| Standards | ISO and Others |

| Sample | Aviailable |

| Available Software | CAD and Others |

| Casting Type | Centrifugal Casting or Sand Casting |

| Service Type | OEM |

| Technology | Centrifugal Casting or Sand Casting |

| Transport Package | Wooden Box |

| Specification | Customized |

| Trademark | OEM |

| Origin | China |

| Production Capacity | 120000 PCS/Year |

Product Description

GYOUSAN is a highly experienced and professional manufacturer of customized casting and CNC machining parts based in Zhejiang. With over 36 years of expertise in machinery parts, we have established ourselves as a trusted partner for businesses seeking high-quality OEM parts.

Our copper casting products are widely used in mining equipment, shipping machinery, wind power, hydropower, heavy machinery and other equipment, committed to developing higher-end precision machinery parts processing. Product Parameters

Properties of copper alloy casting products

| Numbering alloys | Method of casting | Mechanical properties, not less than | |||

| Tensile strength /Mpa | Yield strength 0.2/Mpa | Elongation 5/% | Hardness HB | ||

| Phosphor bronzeZCuSn10P1 | Sand casting | 220 | 130 | 3 | 78.50 |

| Centrifugal casting | 330 | 170 | 4 | 88.50 | |

| Lead bronze ZCuSn10PB5 | Sand casting | 195 | / | 10 | 68.50 |

| Centrifugal casting | 245 | / | 10 | 68.50 | |

| Al-Fe bronze ZCuAl9Fe4 | Sand casting | 490 | 180 | 13 | 98.10 |

| Centrifugal casting | 540 | 200 | 15 | 108.00 | |

| Manganese bronze ZCuAl9Fe4Mn3Ni2 | Sand casting | 654 | 280 | 20 | 157.00 |

| Centrifugal casting | 670 | 310 | 18 | 166.50 | |

| High lead bronze ZCuPb10Sn10 | Sand casting | 180 | 80 | 7 | 63.50 |

| Centrifugal casting | 220 | 110 | 6 | 68.50 | |

| High lead bronze ZCuPb15Sn8 | Sand casting | 170 | 80 | 5 | 59.00 |

| Centrifugal casting | 220 | 100 | 8 | 63.50 | |

| High lead bronze ZCuSn5Zn5Pb5 | Sand casting | 200 | 90 | 11 | 59.00 |

| Centrifugal casting | 250 | 100 | 13 | 63.50 | |

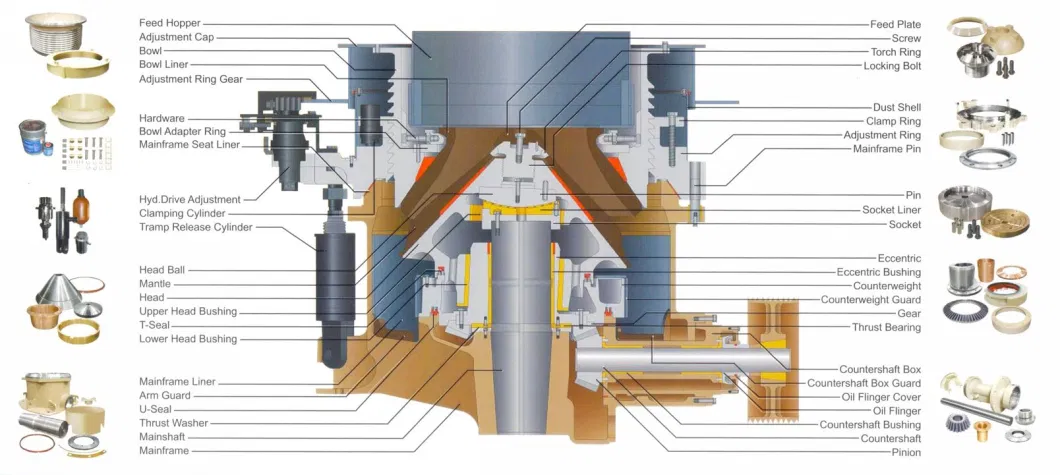

Copper parts of cone crusher

Copper bushings of Excavator Copper bearings Engineering machinery Copper bushings of Rubber machinery

Materials:ZCuPb24Sn5 Size:Φ1448*Φ1185*1387

Net weight:1310KG Bronze bushings of gyratory crusher 5065,4265 Copper bushings cooperated with Telsmith USA Ball bushings of P&H electric shovel Materials:ZCuZn23Al6Fe3 Mn2 Net weight:6T P&H big size copper bushing Copper bushings of Press machine 35000T Copper pressing bushings Materials:ZCuZn23Al6Fe3Mn2 Materials:ZCuSn7Zn4Pb6 Materials:ZCuAl10Fe4Ni4 Size:φ2844*Φ2744*Φ2593*685 Size:1710*1650*1195,Net weight:1100KG Net weight:802kg Copper parts of ball grinder Φ6.2*9.5,lining tile ZCuPb15Sn8,Φ2881*2610*750 Copper nut, ZCuZn23Al6Fe3Mn2, Net weight: 4050KG

Standard JB/T 4730.5-2005 to I gradeProduct Description

Copper and steel parts of FIVE series cone crushers

1. HP Cone Crushers series-Copper and steel parts of multicylinder cone crusher

Model:HP200,HP300,HP400 ,HP500,HP700,HP800,HP4,HP5,HP6

2. MP Cone Crushers series-Copper parts

Model:MP800,MP1000,MP1250

3. GP Cone Crushers series-Copper parts of single cylinder cone crusher

Model:GP100,GP220,GP300,GP500,GP550,GP11,GP100S,GP200S

4. SG Gyratory Crushers series-Copper parts of gyratory crusher

Model:SG4265,SG5065,SG6089

5. H&CH&S&CS Crushers series-Copper parts of single cylinder cone crusher

Model:H(S)300,H(S)3800,H(S)4000,H(S)4800,H(S)6000,H(S)6800,H7800,H8800, CH(CS)420,CH(CS)430,CH(CS)660,CH870,CH880,CH890,CH895

Company Profile

GYOUSAN is a highly experienced and professional manufacturer of customized casting and CNC machining parts based in Zhejiang. With over 36 years of expertise in machinery parts, we have established ourselves as a trusted partner for businesses seeking high-quality OEM parts.

Certifications

1. What is your quotation element?Design drawing (including material, weight, process, surface treatment, special requirements,etc.) or sample, order quantity.2. Do you accept the 3D drawings?We accept 3D drawings. Software for specification drawings: Auto CAD, Solid work3. How long can I get the price?Price will be quoted within 24 hours after we get your inquiry with detailed information.4. What is your payment term?Usually we use TT payment, and the prepayment proportion is determined according to the order quantity, but mold and sample cost need to be paid in advance. 5. What's your delivery time ?The sample delivery time is generally about 10-30 days(including mold making time), and the order delivery period is determined by the order quantity.Normally, 15-40 days after receiving the advance.6.What about your quality?All of our products have good quality. Each casting is processed through our QC staff with inspection records for every shipment. To guarantee the correct material specification and right mechanical properties, we have chemical analysis equipment, hardness tester, and tensile strength machine.

Prev: Gp11f Cone Crusher Spare and Wear Parts Thrust Bearing

Next: Gp200s Cone Crusher Spare and Wear Parts Thrust Bearing

Our Contact