CNC Machinery Motorcycle Oil Pump Lock Tools Textile Diesel Engine Gearbox Transmission Reducer Bearing Gear Spare Powder Metallurgy Components

Description

Basic Info.

| Surface Treatment | Spray-Paint |

| Surface Roughness | Ra6.3 |

| Standard | DIN |

| Certification | CE, ISO 9001:2000 |

| Paint | Powder Coated |

| Other Material | Gray Iron, Ductile Iron, Al |

| Transport Package | Polywood Cases |

| Specification | 10kg-300kg |

| Origin | China |

| HS Code | 847490000 |

| Production Capacity | 100000 Pieces Per Year |

Product Description

Product DescriptionHebei Excellent Machinery Tech. LTD is a machinery spare parts supplier from China for decades. The processes of the vibrator motor cases we could supply resin sand casting and lost-foam casting, etc.The raw parts' weight between 10kg to 300kgs . we could also make surface treatment like powder coated, painting etc. We are the one stop shop for you!

Detailed PhotosCompany ProfileHebei Excellent Machinery Tech. Co., Ltd. provides cast iron and steel components in North China.

Since 1997, we are in the business of these products and exported the products to USA and EU.We have following methods to produce:1. Automatic line, model box at 900X9002.Shell moulding3.Lost wax casting4.Machining from Tube, bar5.Steel sheet cutting and machining

We have special advantage in the following products:1. Components for agricultural equipment, construction and mining equipment, typical products include: wheel hubs, wheels, counter weight , 3 points for lifting system, etc.2. Pump body, motor housing and valve body castings.3. Concrete hose fittings4. Pulleys, pulleys for glazing line.Weight of castings we could supply: up to 5MT.Dimension of castings: up to 2.5 Meter.

Material of castings: gray iron, ductile iron, carbon and alloy steel, investment stainless steel castings, etc .Our machine shop are equipped with both engine lathe for rough machining and CNC, MCs for finishing to meet the tolerance requirement and at the same time to maintain the lowest cost.

Physical Test: Hardness, Tensile strength, yield strength, elongation.Chemical Test: C,Si,Mn,S,P and so on.Surface treatment: Powder coating, Galvanization, Mirror polishing etc

We have experienced technicians, advanced equipment, modern and efficient management methods, reliable quality, and a policy of regarding the customer as the heart of service will ensure the continuous and steady development of our company. You can count on our expertise, including a staff foundry engineer, to assist in providing the best solution to lower the cost of your final products.

We will, as always, work together with our customers to seek opportunities for developing new market and products, to satisfy our customer and the society.

With more than 20 years experience in casting and machining exportation, HEM Tech has kept on good terms with customers in business. The following will make you trust us:

1. Reliable qualityQuality is as important as our life. To make our products reliable, we have employed professional engineers and introduced a series of quality control system.2. Competitive priceWe can offer the best price as well as reliable products for you.3. Reasonable deliveryThorough quality control system makes delivery in time.4. Friendly communicationWe treat every customer as our best friend, and we handle each question seriously.5. Professional technical supportOur engineers are ready for your questions.

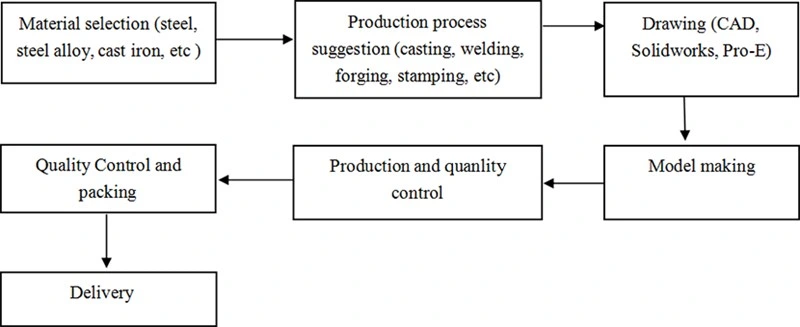

The production work flow chart is as following:

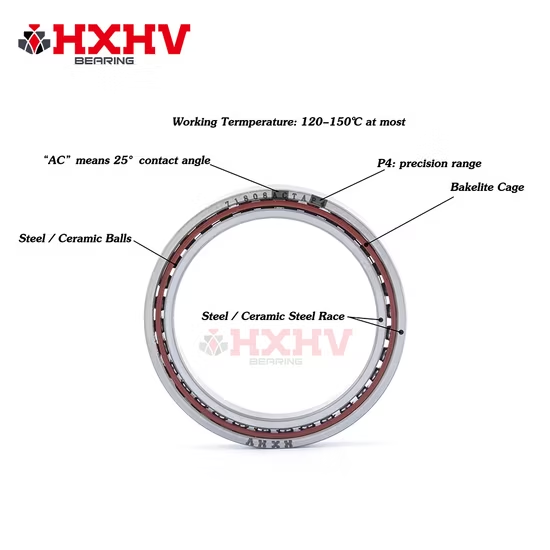

Prev: Thin Section Bearing Ka030cpo Robot Bearing

Next: Custom CNC Machined Iron Casting Bearing Base Components for Rolling Mill Equipment

Our Contact